‘Running Through 23-24

A Season To Remember:

After a 43-23-4-2 regular season record and finishing second in the AHL’s Pacific Division, the Roadrunners finished just short in the first round of the Calder Cup Playoffs versus the Calgary Wranglers. The 43-win season marks the most in a single-season for Tucson all-time; which helped the Roadrunners clinch home ice advantage and bring WhiteOut Tucson to the TCC for the first time since 2018.

Tucson Roadrunners Road Ahead: Road To The Cup Begins

On Friday, April 19, the Arizona Coyotes reassigned Dylan Guenther, Josh Doan and Michael Kesselring to the Roadrunners. Michael Kesselring was the first recall of the group on November 8; playing just the first six games for the Roadrunners. He would go on to have his breakout season in the NHL; tallying five goals and 16 assists for 21 points; with a plus/minus of +11 in 65 games. Guenther was the second to be called up on January 6; playing 45 games with the Coyotes and scoring 18 goals and 17 assists for 35 points. Doan was the last recall of the three on March 25; combining five goals and four assists for nine points in his first 11 career NHL games. This season, the Roadrunners saw a record-breaking 19 player recalls this season; with six of them making their NHL debuts including: Matthew Villalta, Josh Doan, Max Szuber, Patrik Koch, Cam Crotty and Aku Raty. 167 NHL games were played between 14 different Roadrunner skaters this season; in which they all combined for 30 goals and 45 assists for 75 points.

Conor Geekie Assigned To The Tucson Roadrunners By The Arizona Coyotes

Tucson, Arizona – The Tucson Roadrunners and General Manager John Ferguson announced Sunday that 2022 11th overall pick Conor Geekie has been assigned to the Tucson Roadrunners from the Swift Current Broncos by the Arizona Coyotes ahead of the Calder Cup Playoffs.

Roadrunners Finish In Second Place; Will Host Calgary In First Round of Playoffs

Tucson, Arizona - The Tucson Roadrunners will host the Calgary Wranglers in the First Round of the 2024 Calder Cup Playoffs in a matchup solidified on the final day of the AHL’s regular season after Colorado beat Ontario 6-3.

Josh Doan, Dylan Guenther and Michael Kesselring Assigned To The Tucson Roadrunners For The Calder Cup Playoffs; Raty, Kolyachonok Rejoin Too

Tucson, Arizona – The Tucson Roadrunners and General Manager John Ferguson announced today that forwards Dylan Guenther and Josh Doan, along with defenseman Michael Kesselring; have been Assigned to Tucson by the Arizona Coyotes ahead of the round one of Calder Cup Playoffs.

Josh Doan Named To AHL’s All-Rookie Team

Tucson, Arizona - The Tucson Roadrunners have announced dates for their 2024 WhiteOut Tour leading up to the Road to the Calder Cup.

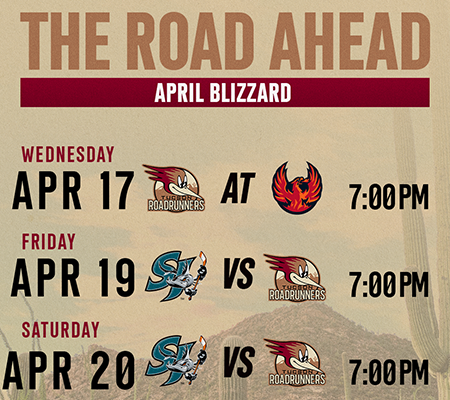

Tucson Roadrunners Road Ahead: April Blizzard

WhiteOut Clinched:

On Saturday, April 13, the Roadrunners clinched home ice advantage for the first round of the Calder Cup Playoffs. Ben McCartney scored the game winning goal at the 5:55 mark of the third period to give the Roadrunners the lead and the 2-1 win; bringing WhiteOut Tucson back to Southern Arizona for the first time since 2018. The last time Roadrunners hosted a playoff game in the 2017-18 season: the team finished 42-20-5-1 in 68 games played. Those 42 wins are the most the team has in a single season along with 90 points. The 2023-24 Roadrunners have three remaining games to earn the most wins and points in a regular season: currently at 41 wins and 87 standings points.

Dates For 2024 WhiteOut Tour Announced

Tucson, Arizona - The Tucson Roadrunners have announced dates for their 2024 WhiteOut Tour leading up to the Road to the Calder Cup.

First Round Whiteout Schedule Announced

Tucson, Arizona - The Tucson Roadrunners have announced their schedule for the First Round of the Whiteout and the 2024 Calder Cup Playoffs after officially clinching home ice advantage in the first round series on Saturday night in a 2-1 win over Colorado at Tucson Arena.

Roadrunners Televising Game On My 18 On Saturday April 13th

Tucson, Arizona – The Roadrunners will televise their game in Southern Arizona on Saturday, April 13th when they host the Colorado Eagles from Tucson Arena on the team’s Official TV Station My 18 (KTTU). Coverage begins the same time as puck drop at 7:00 p.m. MST.

Cameron Hebig Named Roadrunners Man of the Year

Tucson, Arizona – The Tucson Roadrunners are proud to announce that forward Cameron Hebig has been named the team’s winner of the IOA/American Specialty AHL Man of the Year award for his outstanding contributions to the Tucson community during the 2023-24 season.

Tucson Roadrunners Road Ahead: The Push For Home Ice

The New Kid On The Block:

The Roadrunners newest forward Sam Lipkin was signed to a three-year entry level contract on Thursday, April 5 by the Arizona Coyotes and was assigned to the Tucson Roadrunners to help the playoff push. The former Quinnipiac forward impressed in his first two career AHL games in San Diego; notching an assist in his first career game paired with forward Austin Poganski and Cameron Hebig. Lipkin fills in the role similar to Josh Doan on Tucson’s playoff push last season. In 14 games played after being signed to an entry level contract by the Arizona Coyotes during the 2022-23 season. The Arizona native helped Tucson make the playoffs with six points (3 goals, 3 assists) in 14 games played; and added an assist in three games for the first round of the Calder Cup Playoffs.